Enerpac hydraulic pumps are renowned for their reliability and innovative design, providing efficient power solutions across various industries. This guide offers a comprehensive overview of their operation, maintenance, and troubleshooting, ensuring optimal performance and safety.

1.1 Overview of Enerpac Hydraulic Pumps

Enerpac hydraulic pumps are high-performance tools designed for various industrial applications, offering reliability and durability. Known for their advanced engineering, these pumps provide precise control and efficient power transmission. They are widely used in construction, manufacturing, and oil & gas industries for tasks like lifting, pressing, and bolting. Available in manual, electric, and pneumatic models, Enerpac pumps cater to diverse operational needs. Their robust design ensures long-term functionality, making them a preferred choice for professionals seeking dependable hydraulic solutions.

1.2 Importance of the Enerpac Hydraulic Pump Manual

The Enerpac Hydraulic Pump Manual is a vital resource for operators, providing detailed guidance on safe operation, maintenance, and troubleshooting. It covers essential procedures, technical specifications, and safety protocols, ensuring optimal performance and compliance with industry standards. By following the manual, users can prevent accidents, extend equipment lifespan, and maintain operational efficiency. It is an indispensable tool for anyone working with Enerpac hydraulic pumps, ensuring reliability and safety in all applications.

Understanding the Enerpac Hydraulic Pump Manual

The Enerpac hydraulic pump manual is a comprehensive guide detailing operation, maintenance, and troubleshooting procedures. It ensures safe and effective use of the pump, catering to both novice and experienced users.

2.1 Structure and Layout of the Manual

The Enerpac hydraulic pump manual is organized into clear, logical sections, ensuring easy navigation. It begins with an introduction, followed by safety guidelines, key components, operation, maintenance, and troubleshooting. Each section is divided into subsections with headings, subheadings, and bullet points for clarity. Diagrams, charts, and tables are included to illustrate complex concepts. The manual’s appendices provide additional resources, such as technical specifications and error codes. This structured approach ensures users can quickly locate the information they need, making it a practical and user-friendly resource.

2.2 Key Sections of the Manual

The Enerpac hydraulic pump manual includes essential sections like safety guidelines, technical specifications, and operating instructions. It also covers maintenance schedules, troubleshooting, and parts identification. Each section is designed to provide clear, actionable information, ensuring users can safely and effectively operate and maintain their hydraulic pumps. The manual also includes diagrams and charts to aid understanding, making it a comprehensive resource for both novice and experienced users. Properly following the manual ensures optimal performance and longevity of the equipment.

2.3 How to Navigate the Manual Effectively

To navigate the Enerpac hydraulic pump manual effectively, start by reviewing the table of contents to locate specific sections quickly; Use the index to find detailed topics or components. Familiarize yourself with the manual’s structure, as related information is often grouped together. Utilize the search function in digital versions to pinpoint keywords or phrases. Pay attention to visual aids like diagrams and charts, which provide clear guidance. Refer to cross-referenced pages for additional details on complex topics. This systematic approach ensures efficient access to critical information.

Safety Guidelines and Precautions

Adhering to safety guidelines is crucial when working with Enerpac hydraulic pumps. Always wear protective gear, follow manual instructions, and be aware of potential hazards to prevent accidents.

3.1 General Safety Considerations

When working with Enerpac hydraulic pumps, prioritize safety to prevent accidents and ensure smooth operation. Always wear protective gear, including gloves and safety goggles. Ensure the pump is placed on a stable, level surface and follow the recommended pressure guidelines. Avoid overloading the system, as this can lead to equipment failure. Use only genuine Enerpac parts to maintain performance and safety standards. Regularly inspect hoses and connections for leaks or damage. Keep the work area well-ventilated and free from flammable materials. Adhere to the manual’s instructions and ensure all personnel are properly trained. Never bypass safety features or ignore warning signs. Always lock out the system during maintenance to prevent unexpected start-ups.

3.2 Handling and Storage Safety

Proper handling and storage of Enerpac hydraulic pumps are crucial to ensure longevity and safety. Always use approved lifting techniques to avoid damage or injury. Store the pump in a clean, dry environment, away from direct sunlight and moisture. Use the original packaging or equivalent protection to prevent scratches or dents. Check for any damage before storing and follow manufacturer guidelines for disposal of damaged components. Regularly inspect stored units to maintain operational readiness and safety standards.

3.3 Emergency Procedures

In case of hydraulic pump failure or fluid leakage, immediately shut off the power supply and isolate the system. Contain spills using absorbent materials to prevent environmental damage. Wear protective gear, including gloves and safety glasses, when handling hazardous situations. For high-pressure issues, slowly relieve pressure according to the manual’s guidelines. Ensure all emergency procedures are documented and communicated to personnel. Regular training on emergency protocols is crucial for safe and effective response. Always refer to the manual for specific instructions tailored to your Enerpac hydraulic pump model.

Key Components of the Enerpac Hydraulic Pump

The Enerpac hydraulic pump consists of a robust pump assembly, a high-efficiency motor, precise control valves, and a durable reservoir, ensuring reliable and consistent hydraulic performance.

4.1 Hydraulic Pump Assembly

The hydraulic pump assembly is the heart of the Enerpac system, responsible for converting electrical energy into hydraulic energy. It consists of a robust pump housing, a high-performance piston, and a precision-engineered valve system. Designed for durability, the assembly incorporates advanced materials and coatings to withstand extreme operating conditions. Proper alignment and installation of the pump assembly are critical for optimal performance. Regular inspection and maintenance ensure prolonged service life and reliable operation in demanding industrial environments.

4.2 Motor and Drive System

The motor and drive system are critical components of the Enerpac hydraulic pump, ensuring efficient power transmission. Electric motors are commonly used, offering high reliability and ease of integration. Hydraulic motors are also available for specific applications. The drive system includes gears, bearings, and couplers, designed to minimize wear and maximize performance. Regular lubrication and alignment checks are essential to maintain optimal functionality. Proper maintenance ensures the motor and drive system operate smoothly, delivering consistent power to the hydraulic pump.

4.3 Control Valve and Accessories

The control valve is a critical component of the Enerpac hydraulic pump, regulating fluid flow and pressure. Accessories like pressure gauges, relief valves, and adapters enhance functionality. Proper installation and maintenance ensure optimal performance and safety. Always refer to the manual for specific guidelines on handling these components.

Regular inspection of the control valve and accessories is essential to prevent malfunctions. Ensure all parts are compatible with the pump’s specifications for reliable operation.

4.4 Reservoir and Fluid System

The reservoir is a critical component of the Enerpac hydraulic pump, storing the hydraulic fluid essential for operation. It is typically constructed from durable materials to withstand harsh environments. The reservoir is equipped with features like baffles to minimize fluid aeration and ensure smooth flow. Proper fluid level and cleanliness are vital for optimal performance. The fluid system includes suction strainers and return-line filters to prevent contamination. Regular maintenance, such as checking fluid levels and condition, ensures the system operates efficiently and prolongs pump lifespan.

Operating the Enerpac Hydraulic Pump

Operating an Enerpac hydraulic pump involves pre-operation checks, starting procedures, pressure adjustments, and continuous monitoring to ensure efficient and safe performance. Always follow manual guidelines for optimal results.

5.1 Pre-Operation Checks

Before operating an Enerpac hydraulic pump, perform thorough pre-operation checks to ensure safe and efficient functionality. Inspect the pump, hoses, and connections for damage or leaks. Check the hydraulic fluid level and viscosity, ensuring it meets specifications. Verify that all valves are in the correct position and that the pressure gauge is functioning properly. Test the control functions to ensure smooth operation. Review safety protocols and wear protective equipment. These steps help prevent accidents and maintain optimal performance.

- Inspect for damage or leaks.

- Check fluid levels and viscosity.

- Verify valve positions and gauge functionality.

- Test control functions.

- Review safety protocols.

5.2 Starting and Stopping the Pump

Starting and stopping the Enerpac hydraulic pump requires careful attention to ensure smooth operation and prevent damage. Always ensure the system is depressurized before starting. Turn the control valve to the “start” position and monitor pressure gauges. For stopping, gradually reduce pressure and engage the stop mechanism. Refer to the manual for specific startup and shutdown sequences to maintain safety and efficiency. Always follow safety protocols to avoid sudden system failures or fluid leaks.

- Depressurize the system before startup.

- Follow the manual’s startup sequence.

- Monitor pressure during operation.

- Engage the stop mechanism slowly.

5.3 Adjusting Pressure and Flow Settings

Adjusting pressure and flow settings on an Enerpac hydraulic pump ensures optimal performance for specific tasks. Refer to the manual for recommended pressure ranges and flow rates. Use the control valve to fine-tune settings, ensuring smooth operation. Always monitor system response to avoid over-pressurization. Adjustments should align with the application’s requirements, and safety guidelines must be followed to prevent equipment damage or operational hazards. Regular checks and precise calibration are essential for maintaining efficiency and reliability.

5.4 Monitoring Pump Performance

Regular monitoring of the Enerpac hydraulic pump ensures optimal operation and prevents potential issues. Check pressure gauges, flow rates, and temperature levels to ensure they remain within specified limits. Listen for unusual noises or vibrations, which may indicate wear or misalignment. Inspect fluid levels and condition, topping up as needed. Use the manual’s guidelines to interpret performance data and address any deviations promptly. This proactive approach helps maintain efficiency, prevents overheating, and extends the pump’s lifespan. Always refer to the manual for specific monitoring procedures.

Maintenance and Servicing

Regular maintenance is crucial for extending the lifespan and efficiency of Enerpac hydraulic pumps. Routine inspections, fluid checks, and component replacements ensure optimal performance and prevent unexpected failures.

6.1 Routine Maintenance Schedule

Regular maintenance is crucial for ensuring the optimal performance and longevity of Enerpac hydraulic pumps. A routine schedule should include checking fluid levels, inspecting hoses and connections for wear, and cleaning or replacing filters. Additionally, lubricating moving parts and monitoring pump performance metrics is essential. Always adhere to the manufacturer’s recommended maintenance intervals to prevent unexpected downtime and ensure operational efficiency. Proper record-keeping of maintenance activities helps track the pump’s condition and plan future servicing effectively.

6.2 Troubleshooting Common Issues

Common issues with Enerpac hydraulic pumps include low pressure, fluid leaks, and motor malfunction. Always refer to the manual for diagnostic steps. Check fluid levels, inspect hoses for damage, and ensure proper valve alignment. If pressure is inconsistent, examine the pump’s relief valve and adjust as needed. For motor issues, verify electrical connections and consult error codes. Regular maintenance can prevent many problems. If unresolved, contact Enerpac support for professional assistance.

6.3 Repair and Replacement Procedures

Repair and replacement procedures for Enerpac hydraulic pumps require careful planning and adherence to the manual. Identify faulty components, such as seals or valves, and replace them with genuine Enerpac parts. Ensure proper disassembly and reassembly techniques to maintain system integrity. Always follow torque specifications and lubrication guidelines. After replacement, perform a pressure test to verify functionality. Consult the manual for detailed step-by-step instructions to ensure safety and compliance with manufacturer standards. Regular maintenance can prevent premature wear and extend pump lifespan.

Technical Specifications and Requirements

Enerpac hydraulic pumps are designed with precise technical specifications, including pressure ratings, flow capacities, and fluid compatibility. These requirements ensure optimal performance and compliance with industry standards.

7.1 Hydraulic Pump Specifications

Enerpac hydraulic pumps are designed with precision, offering a range of specifications to meet diverse industrial needs. Key details include maximum pressure ratings, flow rates, and motor types. Pressure ratings vary from 1,000 to 10,000 psi, while flow rates range from 0.5 to 10 gpm. Motor options include electric, pneumatic, and hydraulic drives. Fluid compatibility is critical, with recommendations for hydraulic oils and operating temperatures. These specifications ensure optimal performance, efficiency, and durability in various applications. Always refer to the manual for exact details tailored to your model.

7.2 Fluid Requirements and Compatibility

Enerpac hydraulic pumps require specific fluid types to ensure optimal performance and longevity. The recommended fluid is a high-quality, anti-wear hydraulic oil with a viscosity range of 32-68 cSt. Operating temperatures should not exceed 65°C (150°F) to prevent fluid degradation. Ensure compatibility with system materials, as incorrect fluids can cause corrosion or seal damage. Always refer to the manual for approved fluid specifications and additives. Using non-approved fluids may void warranties or lead to premature system failure. Proper fluid selection is critical for reliable operation.

7.3 Operating Conditions and Limits

Enerpac hydraulic pumps are designed to operate within specific temperature, pressure, and fluid viscosity ranges. Maximum operating pressure varies by model, typically ranging from 1,000 to 10,000 psi. Ambient temperatures should be between -20°F and 140°F (-29°C to 60°C) for optimal performance. Fluid viscosity must align with pump specifications to ensure efficiency and longevity. Exceeding these limits can lead to reduced performance, increased wear, or potential system failure. Always refer to the manual for model-specific operating parameters to ensure safe and reliable operation.

Applications of Enerpac Hydraulic Pumps

Enerpac hydraulic pumps are widely used in industrial, construction, and oil & gas sectors for powering machinery, lifting heavy loads, and managing fluid systems efficiently and reliably.

8.1 Industrial Applications

Enerpac hydraulic pumps are widely used in industrial settings for their durability and precision. They power machinery, lift heavy loads, and drive equipment in manufacturing and metalworking. Their compact design and high-pressure capabilities make them ideal for applications like metal stamping, assembly lines, and material handling systems. Additionally, they are used in automated systems and process control, ensuring efficient and reliable operation. Their versatility and performance make them a cornerstone in modern industrial workflows, enhancing productivity and safety across various sectors.

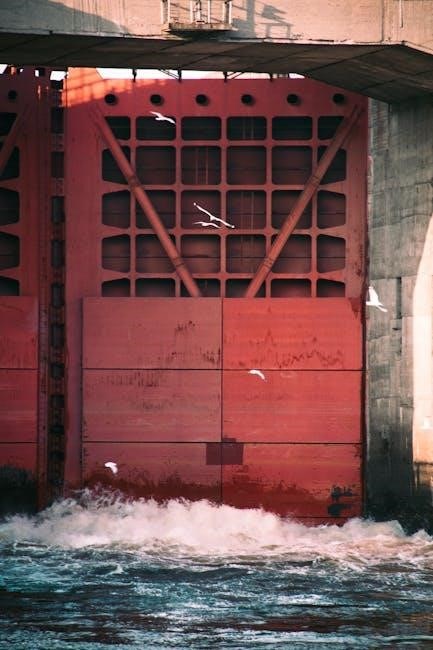

8.2 Construction and Heavy Machinery

Enerpac hydraulic pumps are indispensable in construction and heavy machinery, powering equipment like hydraulic excavators, bulldozers, and concrete pumps. Their high-pressure capabilities ensure consistent performance in demanding environments. These pumps are ideal for lifting, moving, and manipulating heavy loads, making them essential for large-scale projects. Their durability and reliability minimize downtime, ensuring efficient operation in construction sites. Whether for demolition, excavation, or material handling, Enerpac pumps deliver the power and precision needed to meet rigorous construction demands.

8.3 Oil and Gas Industry Applications

Enerpac hydraulic pumps are widely used in the oil and gas industry for their durability and reliability in demanding environments. They power drilling equipment, well control systems, and pipeline maintenance tools, ensuring efficient operations. Their high-pressure capabilities make them ideal for applications requiring precise control, such as wellbore pressure management and heavy machinery actuation. Enerpac pumps are designed to withstand harsh conditions, including extreme temperatures and corrosive substances, making them a critical component in upstream and downstream oil and gas operations.

Downloading and Accessing the Manual

The Enerpac hydraulic pump manual PDF can be downloaded from official sources, ensuring easy access to essential operating and maintenance guidelines for optimal performance and safety.

9.1 Official Sources for the Manual

The Enerpac hydraulic pump manual is available through authorized distributors, the official Enerpac website, and certified service centers. These sources ensure authenticity and accuracy, providing reliable guidance for operation, maintenance, and troubleshooting. Always verify the manual’s source to avoid counterfeit or outdated versions. Official sources may also offer additional support, such as updated revisions or complementary technical resources. For the most accurate information, refer to the manufacturer’s official channels or contact their customer support directly.

9.2 How to Download the PDF

To download the Enerpac hydraulic pump manual PDF, visit the official Enerpac website or authorized distributors. Navigate to the “Support” or “Resources” section, select your specific pump model, and click the download link. Ensure the source is trusted to avoid unauthorized versions. The manual is typically available in PDF format for easy access and printing. Always verify the document’s authenticity before use to ensure accuracy and safety.

9.3 Verifying the Authenticity of the Manual

To ensure the Enerpac hydraulic pump manual is genuine, verify it through official Enerpac sources or authorized distributors. Check for digital signatures, watermarks, or official logos. Compare the document version with the manufacturer’s website. Cross-reference critical information, such as specifications and safety guidelines, with trusted resources. Contact Enerpac support for confirmation if unsure. An authentic manual is essential for safety, compliance, and proper equipment operation. Always avoid using unverified documents to prevent potential risks.

Using the Manual for Troubleshooting

The manual provides detailed diagnostic procedures, error codes, and solutions, enabling users to identify and resolve issues efficiently, ensuring optimal pump performance and minimizing downtime.

10.1 Identifying Common Issues

Common issues with Enerpac hydraulic pumps include low pressure output, excessive noise, and fluid leaks. These problems often stem from worn seals, clogged filters, or improper fluid levels. Monitoring performance metrics and paying attention to unusual sounds or vibrations can help identify issues early. Regular maintenance, as outlined in the manual, is crucial for preventing these problems. Always refer to the troubleshooting section for specific guidance on diagnosing and addressing these common concerns effectively.

10.2 Diagnostic Procedures

Diagnosing issues with Enerpac hydraulic pumps involves a systematic approach to identify faults. Start with a visual inspection of connections, hoses, and components for damage or leaks. Check fluid levels and condition, ensuring cleanliness and compatibility. Review error codes or unusual noises to pinpoint problems. Use pressure gauges and flow meters to measure performance against specifications. Consult the manual for troubleshooting charts and procedures. Always follow safety guidelines when performing diagnostics to avoid further damage or personal injury.

10.3 Error Codes and Solutions

The Enerpac hydraulic pump manual provides a detailed list of error codes and their corresponding solutions. These codes help identify specific issues, such as low fluid levels or overheating. For example, error code E001 may indicate a malfunctioning pressure sensor, while E002 could signal excessive temperature levels. The manual offers step-by-step solutions, such as checking fluid levels or inspecting cooling systems. Understanding these codes enables quick troubleshooting, ensuring minimal downtime and optimal pump performance. Always refer to the manual for precise diagnostic and repair guidance;

Compliance and Regulations

Enerpac hydraulic pumps must adhere to industry standards and certifications, ensuring environmental and safety compliance. Proper documentation and adherence to regulations are crucial for legal and operational integrity.

11.1 Industry Standards and Certifications

Enerpac hydraulic pumps are designed to meet rigorous industry standards and certifications, ensuring reliability and safety. They comply with ISO, CE, and other global standards, reflecting their commitment to quality. These certifications guarantee adherence to international safety and performance requirements, making them suitable for various industrial applications. Understanding these standards is crucial for operators to ensure compliance, optimal performance, and longevity of the equipment.

11.2 Environmental and Safety Regulations

Enerpac hydraulic pumps must comply with environmental and safety regulations to ensure eco-friendly and hazard-free operation. Adherence to standards set by OSHA, EPA, and ISO is crucial. Proper disposal of hydraulic fluids and recyclable materials is emphasized. Safety regulations include protective equipment usage and hazard communication. Regular audits ensure compliance, minimizing environmental impact and workplace risks. Always refer to local and international laws for specific requirements.

This guide provides essential insights into Enerpac hydraulic pumps, ensuring safe and efficient operation. Always refer to the manual for troubleshooting and maintenance, maximizing performance and longevity.

12.1 Summary of Key Points

This guide provides a comprehensive overview of the Enerpac hydraulic pump manual, emphasizing safety, proper operation, and maintenance. It highlights the importance of adhering to manual instructions for optimal performance and longevity. Key components, troubleshooting, and compliance with industry standards are also covered. By following the guidelines, users can ensure efficient, reliable, and safe operation of Enerpac hydraulic pumps across various industrial applications. This summary underscores the essential takeaways for effective and responsible use of the equipment.

12.2 Final Tips for Effective Use

To maximize the performance and longevity of your Enerpac hydraulic pump, always adhere to the manual’s guidelines. Regularly inspect and maintain components, ensure proper fluid levels, and store the pump in a clean, dry environment. Refer to the manual for specific troubleshooting steps and never overlook safety precautions. By following these practices, you can ensure reliable operation, reduce downtime, and extend the lifespan of your equipment. Consistent adherence to the manual will help you achieve optimal results in any application.